Categories

Choose Language

Popular Posts

[mashshare url="https://www.skyfiveproperties.com/blog/steel-vs-aluminum-best-product"]Steel vs Aluminum: Which is Best For Your Product?

Aluminum and stainless are two of the most common metals that are used for manufacturing. They are both extremely versatile and do not corrode easily. This makes stainless steel and aluminum staples in the metals industry.

But if you want the differences and pros and cons when it comes to stainless steel vs aluminum, you need to do a deep comparison. Luckily for you, that is exactly what we have done in this article.

Main Characteristics of Stainless-Steel vs Aluminum

Stainless steel comes in all sorts of grades. The grades are sorted by a series number and given a numerical score.

The number classifies the grade of steel based on its applications, physical properties, and composition. Stainless steel has high tensile strength, is usually magnetic, and contains iron.

Aluminum is not magnetic, has a low density, and does not contain iron.

Thanks to its low tensile strengths, aluminum is usually combined with other metals to give it more properties.

Conductivity

Aluminum is a great thermal and electrical conductor. Stainless steel, on the other hand, is not a good conductor of electricity. This is because of its dense protective oxide layer.

Cost

When it comes to cost, aluminum tends to be more expensive than stainless steel when you are considering the price based on weight. However, if you are looking at cost based on volume then you will see that aluminum is cheaper because you are getting more product.

Of course, you also need to consider manufacturing costs. You can see here to learn more about manufacturing.

Heat Resistance

When we are looking at the differences between two popular metals, it is very important that we compare heat resistance. Stainless steel is much better when it comes to resistance to heat. It has a melting point of 2500 ℉.

Aluminum, on the other hand, becomes soft around 400 ℉. It has a melting point of only 1220 ℉.

With all that said, when it comes to cold temperatures, aluminum has the advantage. As the temperature goes down, the tensile strength of aluminum goes up. Stainless steel, on the other hand, becomes brittle when it gets too cold.

Corrosion Resistance

Although aluminum will not rust, it will corrode when you expose it to salt. Stainless steel is very resistant to corrosion and won’t rust easily.

It should also be pointed out that stainless steel is not porous. This makes it even more resistant to corrosion.

The Importance of Knowing the Differences for Steel vs Aluminum

Hopefully, after reading the above article, you now have a better idea of what the differences are when it comes to steel vs aluminum. As we can see, these two metals each come with their pros and cons. By knowing what you want to manufacture, you will have a better idea of which metal is going to be best for you.

Don’t forget to visit our blog for more helpful articles today!

[mashshare]

Popular Posts:

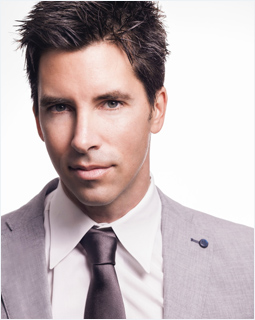

Kaya Wittenburg

Kaya Wittenburg is the Founder and CEO of Sky Five Properties. Since the age of 10, real estate has been deeply ingrained into his thoughts. With world-class negotiation and deal-making skills, he brings a highly impactful presence into every transaction that he touches.

He is here to help you use real estate as a vehicle to develop your own personal empire and feel deeply satisfied along the way. If you have an interest in buying, selling or renting property in South Florida, contact Kaya today.